The Way of Powder Filling Machine Positioning

From semi-automatic auger powder filling machine, to linear automatic powder filling machines, then to the rotary (turntable positioning) high-speed and high-precision powder filling machines. Each step are confirmed the development process of Machinery; Each time technological innovation, we are constantly sum up and improve at the same time.

Here introduce these three kinds machine detailed function:

-

Semi-Automatic Auger Filling Machine

Semi-automatic auger filling machine using photoelectric sensor, or touch the switch, touch the quantitative cutting of the signal, manual splicing. The used of stepper motor or servo motor control quantitative filling.

-

- Advantages:

- Unrestricted for packaging container(suitable for a variety of bottles, cans, tins, jars, bags of quantitative filling)

- Filling high precision (filling accuracy can be controlled within 0.8%)

- High filling speed (up to 7200 bags per hour, please click here for working video)

- Disadvantages: Low degree of automation

- Representative products:

- Semi-automatic small-dose auger filling machine;

- Semi-automatic anti-corrosion auger filling machine.

- Advantages:

-

-

Linear Automatic Filling Machine

Straight-line (linear) automatic filling machine also uses photoelectric induction method, packaging containers (bottles, cans, tins, and jars) through the conveyor belt to reach the filling mouth just below the start control to tighten the device, and then filling.

-

- Advantages:

- Applicable to a variety of bottles, cans, tins of quantitative filling

- Automation has improved

- Disadvantages: Only for the container can be placed in the conveyor belt

- Representative products:

- Linear automatic granule filling machine;

- Linear automatic powder filling machine;

- Linear automatic liquid filling machine.

- Advantages:

-

-

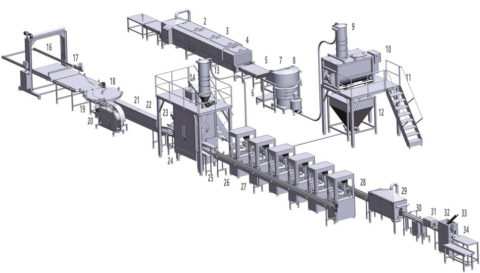

Rotary (Turntable Positioning) High-Speed High-Precision Filling Machine

Rotary (turntable positioning) automatic filling machine adopts rotary, turntable positioning method. Filling containers (bottles, cans, tins, and jars) by the transmission system into the rotating turntable. Turntable multi-station stop, for the filling, sealing and other processes. In order to ensure that these stations can be accurately filling and sealing, turntable equipped with auxiliary photoelectric sensor system.

-

- Advantages:

- Suitable for a variety of bottles, cans, tins, and jars to the quantitative filling.

- High degree of automation

- Can be installed online weighing system, high-precision packaging (packaging accuracy <1.5g, 1000g per can)

- Representative products:

- Automatic powder filling machines;

- High-precision double-heads milk powder filling machine.

- Advantages:

-

Next Post: High-Precision Small Doses Powder Filling Machine