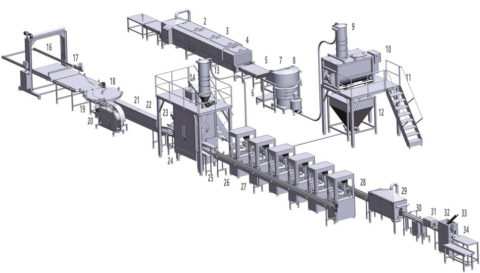

Canned Milk Powder Filling Line Export Malaysia

November 1, 2016. After the first day of Halloween, Malaysia’s canned milk powder filling line and powder quantitative filling machine in the afternoon delivery.

The canned milk powder filling line shipping list mainly includes:

- Double heads High Precision Powder Weighing Filling Machine

- Measurement Methods: Screw filling weighing metering

- Container Size: Φ50-180mm; H: 50-350mm (Cylindrical container)

- Measurement Range: 10-2000g (need to change the screw accessories)

- Filling Accuracy: ± (0.5-2.0) g

- Filling Speed: 8-55 cans/min

- Power: 3P 380V 50Hz 3.5Kw

- Air Pressure: 6-8kg/cm2

- Gas Consumption: 0.2m3 / min

- Machine Weight: 1000Kg

- Dimensions: 3330×1400×2400mm

- Automatic Vacuum Infilling Nitrogen Sealing Machine

Canned Milk Powder Filling Line Export Malaysia - Production Capacity: 8 -10 cans / min

- Cans Diameter: Φ70 – Φ130mm

- Cans Height: 80 -190mm

- Working Pressure (compressed air): ≥0.6MPa

- Air Consumption (compressed air): ≈80L /min

- Nitrogen Gas Pressure: ≥0.4MPa

- Nitrogen Consumption: ≈50L /min

- Lowest Vacuum Pressure: -0.09MPa

- Power: 380V 50Hz 4.0Kw

- Machine Weight: 600Kg

- Dimensions: 2000×900×1850mm

- Powder Packing Machine Unit 50Kg

- Applicable materials: powder, mixed materials

- Measurement range: 2-10 kg, 5-25 kg, 10-50 kg

- Packing accuracy: ± 0.2-0.5%

- Packing speed: 3-6 bags/min

- Feeding method: Screw

- Air pressure: 0.4-0.6Mpa

- Air consumption: 1 m3/h

- Power: 3P 380V 2.2Kw

- Dimensions: 3000×1500×2500mm

Previous Post: Automatic Powder Cans Filling Line Configuration

Next Post: The Way of Powder Filling Machine Positioning