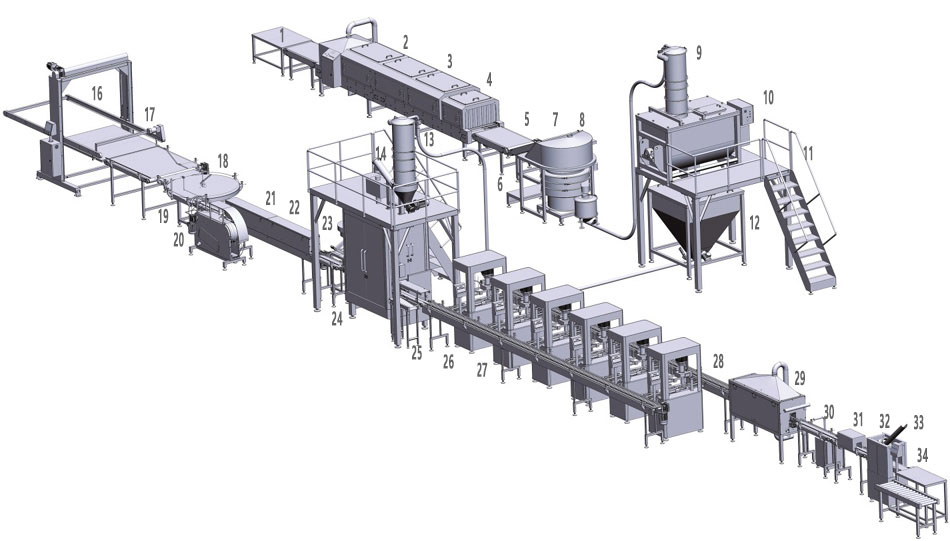

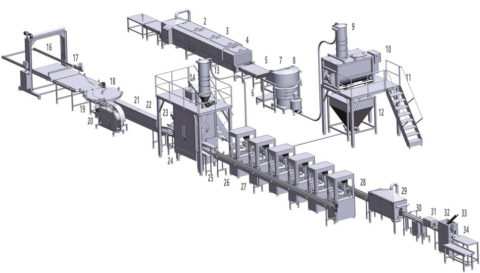

Powder Cans Filling Line Configuration

Automatic Unscrambling cans/tins/bottles/jars, sterilization, automatic canned, vacuumed infilling nitrogen sealing line of milk powder

The system equipment is suitable for milk powder, protein powder, coffee powder and other nutritional powder filling into the cans/tins/bottles/jars. Vacuum cans and infilling nitrogen and sealing, the entire line for the complete line of equipment.

- Packaging Materials: milk powder, protein powder, coffee powder and other nutritional powder.

- Applicable weight: 100-1000 grams

- Cans/tins/bottles/jars Specifications: #300, #307, #401, #502cans; to adapt to high: 60-260mm

- Production Capacity: 7-55cans/min, [the speed depends on the number of vacuum filling nitrogen sealing machine, if equipped with 6 units Sealing Machine, the speed was 48cans/min]

- Single Sealing Machine Speed: 6-9cans/min

- Filling accuracy: ±2grams

- Residual Oxygen: ≤ 3%

- Power Supply: 3phase 380V 50Hz

- Overall Power: 48.33

- Compressed Air: 1.45m3/min, pressure: 6kg/cm2

- Nitrogen: purity> 99.99%, pressure: 0.4Mpa; 3.5 cubic meters / hour / sets, 6 units of demand for 21 cubic meters / hour

The powder cans filling line configuration including: automatic unloading cans, unscrambling cans, empty cans purge, sterilization, filling, distribution cans, vacuum filling nitrogen and sealing, cleaning cans outside, coding, turn cans, pressure cans cover, artificial packing and so on;

The Configuration of Automatic Powder Cans Filling Line

- 1.Bag Dismantle Table

- 2.Conveyor

- 3.Bag Sterilizing Machine

- 4.Conveyor

- 5.Inclined Conveyor

- 6.Powder Falling Table

- 7.Vibrating Screen

- 8.Transition Hopper

- 9.Vacuum Feeder

- 10.Mixer

- 11.Platform

- 12.Storage hopper

- 13.Vacuum Feeder

- 14.Screw Conveyor

- 15.Metal Detector

- 16.Platform

- 17.Automatic Unloading Machine

- 18.Unscrambling Machine

- 19.Conveyor

- 20.Can Turning, Degauss & Blowing Machine

- 21.Empty Cans Sterilizing Machine

- 22.Conveyor

- 23.Spoon Casting Machine

- 24.Automatic Filling Machine

- 25.Conveyor

- 26.Can separator

- 27.Vacuum Nitrogen Seaming Machine

- 28.Conveyor

- 29.Can Cleaning Machine

- 30.Conveyor

- 31.Laser Marking Machine

- 32.Can Turning Machine

- 33.Plastic Lid Capping Machine

- 34.Encasement Table

-

Automatic Can Filling Packing System Unscrambling Machine

Automatic Can Filling Packing System Unscrambling Machine

Automatic Can Filling Packing System Unscrambling Machine

-

Automatic Can Filling Packing System Can Turning Degauss Blowing Machine

Automatic Can Filling Packing System Can Turning Degauss Blowing Machine

Automatic Can Filling Packing System Can Turning Degauss Blowing Machine

-

Automatic Can Filling Packing System Empty Cans Sterilizing Machine

Automatic Can Filling Packing System Empty Cans Sterilizing Machine

Automatic Can Filling Packing System Empty Cans Sterilizing Machine

-

Automatic Can Filling Packing System Automatic Feeder Feeding Machine

Automatic Can Filling Packing System Automatic Feeder Feeding Machine

Automatic Can Filling Packing System Automatic Feeder Feeding Machine

-

Automatic Can Filling Packing System Automatic Powder Filling Machine

Automatic Can Filling Packing System Automatic Powder Filling Machine

Automatic Can Filling Packing System Automatic Powder Filling Machine

-

Automatic Can Filling Packing System Automatic Vacuum Infill Nitrogen Seaming Machine

Automatic Can Filling Packing System Automatic Vacuum Infill Nitrogen Seaming Machine

Automatic Can Filling Packing System Automatic Vacuum Infill Nitrogen Seaming Machine

-

Automatic Can Filling Packing System

-

Automatic Can Filling Packing System

Next Post: Canned Milk Powder Filling Line Export Malaysia

[…] The Configuration of Milk Powder Cans Filling Line Link: https://www.bestpackagingsolutions.cn/automatic-powder-cans-filling-line-configuration […]